Automatic Foreign Particle Scanning Analyzer & Sorting Machine

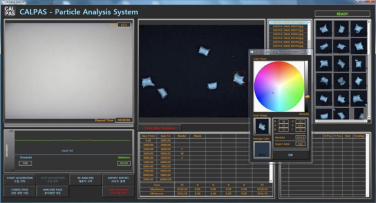

CALPAS

CALPAS

For Foreign Color, Foreign Shape

For Powders, Transparent & Opaque Pellets, Wet Suspension, Film-Tape

Offline to Online

CALPAS, Intelligent Foreign Particle Analyzer

In recent years, the direction of industrial technology has required not only product performance but also management of the unexpected micro objects that have a big influence on ensuring the product’s sustainable performance and clean external appearance. An increase in high-value-added products must be accompanied by a higher level of quality management.

CALPAS (Color [Component] AnaLysis for PArticulate System) is designed to analyze the foreign materials that arise unexpectedly in pellet and powder systems from the petrochemical, plastic, food, and pharmaceutical industries. A quality management system must monitor impurities from production in order to ensure high-quality outcomes.

Measurement of foreign objects is an important factor in determining a product’s quality standard, and only continuous analysis can immediately determine quality. Passive sample analysis performed by humans requires a lot of manpower, and due to human limitations, such analysis is often difficult to conduct. Maintaining stable and consistent product quality—monitoring and controlling the entire process to determine product grade change for “grade pass”—requires a continuous and consistent grasp of quality to optimize production. In the Fourth Industrial Revolution, the recording and sharing of processes and real-time information through the control process is becoming an essential element in the emerging smart manufacturing industry.

For the purpose of the removal and removal, it is expected not only to automate production but also to save money on further investment. The CALPAS online foreign material automatic measuring device, applied to the production site, can be used in a very simple way to quickly and in real time determine the status or quality of the currently manufactured product—and to transfer, store, and use that result.

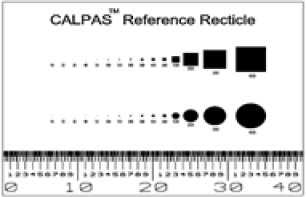

Size Standard (50 micron)

Size Standard (10 micron)

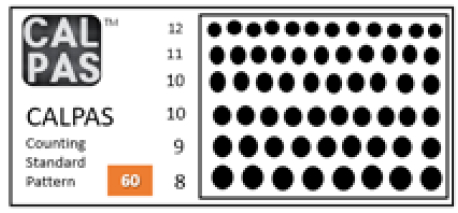

Counting Standard

Shaping Standard

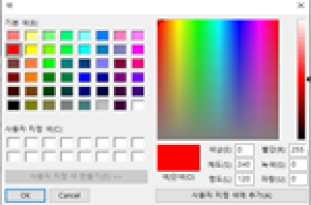

Color Standard (Digital)

CALPAS consists of a high-precision camera, a long working-distance lens, a multidimensional LED illumination system, and software that enables detection of unusual colored particles of dirt and modified variants, or carbonized material differences. It is available to customize CALPAS via modular hardware combinations to cover a variety of options, depending on the application.

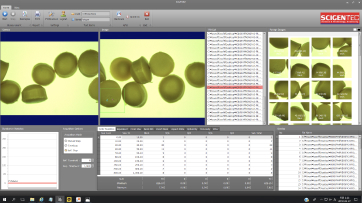

In addition to analyzing material by color and using the same equipment, CALPAS also detects the size and shape of foreign material—characterizing it as long, twin, snakeskin, and other shapes.

CALPAS improves quality management by detecting and diagnosing foreign colored material such as black dots and red, yellow, and other impurities. Unexpected colored particles can greatly impede high-quality appearance and performance.

In addition to general analyses, such as of normal pellets, the device can be configured to analyze transparent pellets—opaque pellets that are very difficult to study without adding AVIDOM, a device specially designed to perform this function. Options can set the minimally detectable amount to 10 µm, at which it is difficult to find foreign bodies in the existing equipment (default specification are 50µm).

Through the system’s modularity and flexibility with regard to light source type and sample supply, precise measurement can take place according to different applications such as with high transparent or opaque pellets and powder. The process of analysis consists of: (1) a reliable supply of the sample, (2) five-dimensional LED illumination composed of four channels with dimming options, (3) high-definition, high-speed cameras, and (4) an intelligent image analysis program that applies an automatic analysis algorithm. All this hardware and software are under the real-time control and analysis process, viewable only a mouse click away.

Supply samples derived from manual or automatic control of the feed rate and speed are available in a very short time. CALPAS provides various information about foreign materials including color, size, and shape in real time and in a report format. The equipment is useful for industries that use PVC, PP, PE, PC, and PMMA from petrochemicals, including the pharmaceuticals, foods, and bulk material industries.

Foreign bodies are detected in real time and registered in a special bin. Each foreign body size, shape, color, and other information is also analyzed in real time. The system is designed so that this data is available for reanalysis at any time. The reanalysis function can be adapted to various additional conditions and other different analysis settings.

Image acquisition and analysis algorithms are optimized using dedicated tools to detect and analyze images collected by hardware in real time for faster processing speed. The separate report function to manage the data from the analyzed results relies on a fast reanalysis speed to apply various detection conditions to measured images in the database.

Intelligent CALPAS software enables users to define the values for foreign color and foreign shape according to market and product quality requirements. The detailed setting function is available in the software as a foreign input and can be set from the stored settings, or the user can choose them in advance. This software programming can provide more precise foreign definition management; a user with only one hardware device available can undertake more direct and detailed management of the foreign body and control and manage the foreign body sustainably according to its requirements.

CALPAS-Basic Program

CALPAS-Pro Program

CALPAS-AI Program